Applications: Construction Companies, Demolition Contractors, Excavation and Earthmoving, Quarries and Mining Operations, Road Construction and Maintenance, Landscaping and Land Clearing Services, Utility and Infrastructure Contractors

Introducing the Kede Side Type Hydraulic Breaker – Your Preferred Solution for Quiet, Energy-efficient, and Environmentally Friendly Demolition!

Kede offers a comprehensive selection of Hydraulic Breakers designed for excavators ranging from 4 to 55 tonnes, compatible with various brands and models. Opt for Kede for a quieter, energy-saving, and eco-conscious rock-breaking experience.

Breaker Hammer & Tools

| Tool Name | Description | Typical Uses |

|---|---|---|

| Blunt Tool | Crushing large rock pieces in quarries | Crushing slag, Ground compression |

| Flat Chisel | General use with additional cutting action | Drawing pits in rocky subsoil, Separating rock slabs |

| Pipe Driver | For driving in pipes | Produced according to request |

| Moil Point | General Use With Demolition Work And in Quarries, Breaking Up Slag In Steel Mills (industrial Application), | Demolishing Foundations, Roadway Driver And Roadway Shots In Mining Forged Point |

| Tamping Tool | Forged plate, 200*200mm, Incl. adaptor for shank ends to max.φ75mm | Compression of ground and gravel |

| Elephant Foot | Demolishing reinforced concrete areas | Crushing large rock pieces in quarries, Ground compression |

| Asphalt Cutter | General use with additional cutting action | Cutting asphalt or soft material |

| Ramming Tool/Post Hole Driver | For beating in poles and pipes | Produced according to request |

| Percussion Buster | For shank ends from φ55 to 180mm | All demolition work in concrete & very tough rock, Special demolition with high cracking action |

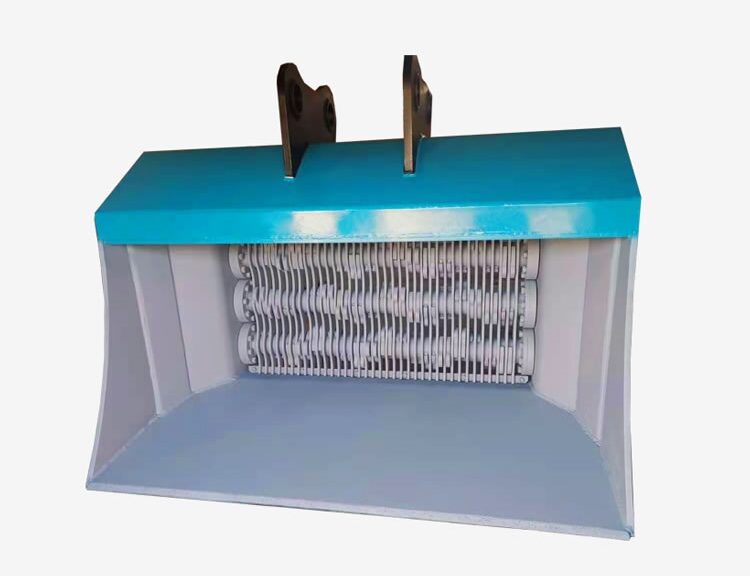

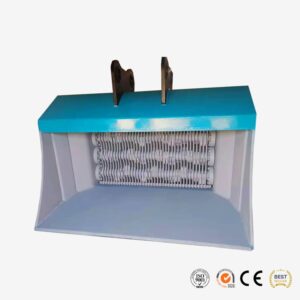

Introducing the Kede Box Type Hydraulic Breaker – Your Top Choice for Quiet, Energy-efficient, and Environmentally Friendly Demolition!

Kede offers a comprehensive lineup of Hydraulic Breakers tailored for excavators ranging from 4 to 55 tonnes, compatible with various brands and models. Choose Kede for a quieter, energy-saving, and eco-conscious breaking solution.

Breaker Hammer & Tools

| Tool Name | Description | Typical Uses |

|---|---|---|

| Blunt Tool | Crushing large rock pieces in quarries | Crushing slag, Ground compression |

| Flat Chisel | General use with additional cutting action | Drawing pits in rocky subsoil, Separating rock slabs |

| Pipe Driver | For driving in pipes | Produced according to request |

| Moil Point | General Use With Demolition Work And in Quarries, Breaking Up Slag In Steel Mills (industrial Application), | Demolishing Foundations, Roadway Driver And Roadway Shots In Mining Forged Point |

| Tamping Tool | Forged plate, 200*200mm, Incl. adaptor for shank ends to max.φ75mm | Compression of ground and gravel |

| Elephant Foot | Demolishing reinforced concrete areas | Crushing large rock pieces in quarries, Ground compression |

| Asphalt Cutter | General use with additional cutting action | Cutting asphalt or soft material |

| Ramming Tool/Post Hole Driver | For beating in poles and pipes | Produced according to request |

| Percussion Buster | For shank ends from φ55 to 180mm | All demolition work in concrete & very tough rock, Special demolition with high cracking action |

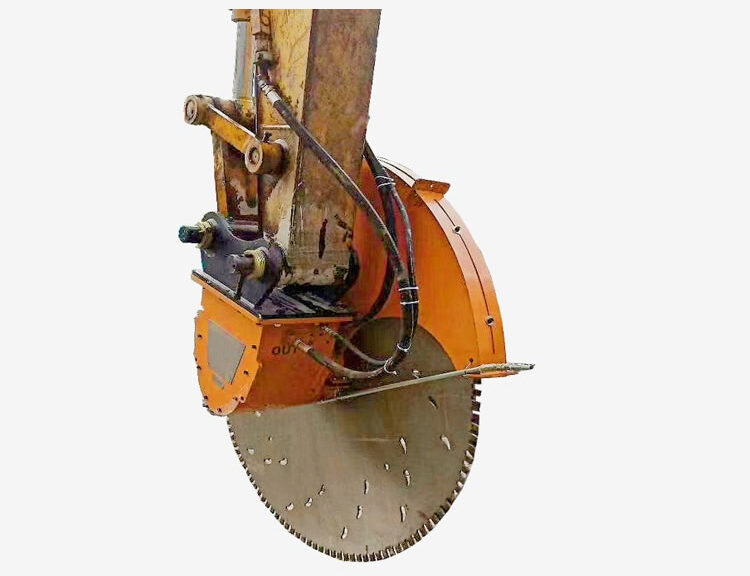

Introducing the Kede Top Type Hydraulic Breaker – Your Premier Choice for Low Noise, Energy Efficiency, and Environmental Responsibility!

Kede offers a comprehensive array of Hydraulic Breakers, perfectly suited for excavators ranging from 4 to 55 tonnes, compatible with various brands and models. Elevate your demolition projects with Kede’s environmentally conscious, energy-saving solution.

Breaker Hammer & Tools

| Tool Name | Description | Typical Uses |

|---|---|---|

| Blunt Tool | Crushing large rock pieces in quarries | Crushing slag, Ground compression |

| Flat Chisel | General use with additional cutting action | Drawing pits in rocky subsoil, Separating rock slabs |

| Pipe Driver | For driving in pipes | Produced according to request |

| Moil Point | General Use With Demolition Work And in Quarries, Breaking Up Slag In Steel Mills (industrial Application), | Demolishing Foundations, Roadway Driver And Roadway Shots In Mining Forged Point |

| Tamping Tool | Forged plate, 200*200mm, Incl. adaptor for shank ends to max.φ75mm | Compression of ground and gravel |

| Elephant Foot | Demolishing reinforced concrete areas | Crushing large rock pieces in quarries, Ground compression |

| Asphalt Cutter | General use with additional cutting action | Cutting asphalt or soft material |

| Ramming Tool/Post Hole Driver | For beating in poles and pipes | Produced according to request |

| Percussion Buster | For shank ends from φ55 to 180mm | All demolition work in concrete & very tough rock, Special demolition with high cracking action |